Expanded metal sheet, after the process of expansion, if necessary, can become several times its original size.

In the process of expansion, the metal sheet material is given a full use with less or zero loss of material compared with metal mesh of other processing method.

To increase the rigidity and corrosion resistance, the expanded metal can be plastic coated.

Because of the structure, expanded metal sheets have great uses as well as the sectors of applications.

Easy for cutting and bending, expanded metal in fine and medium thickness, can be processed in small workshops or even on the spot of application.

| |

|

| |

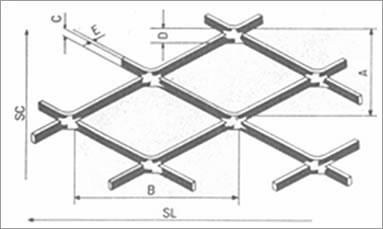

A = Opening of mesh - center to center in the short distance

B = length of the loop – center to center in the long distance

C = Thickness in the long distance

D = The strip

E = thickness of the plate in the short distance

SC = provision cross - mesh - accompanying the width

SL = provision longitudinal - mesh - the length |

The expanded metal floors are expanded plates in big thicknesses with a high mechanical strength. In places where the load is distributed and concentrated largely, greater mechanical strength is required, expanded metal grating floors come.

Strands: The individual slit metal strips, or slides of an expanded metal pattern. Strand Thickness in standard expanded metal is the gauge or thickness of the sheet or coil from which the expanded metal was produced. In flattened expanded metal it is the overall thickness of the finished sheet. Strand Width in standard expanded metal is the amount of metal fed into the expanding machine, which is slit and stretched with each stroke of the upper die. In flattened expanded metal, it is as the name implies, the width of the strand.

Style Designation: Expanded metal products are designated by a series of numbers which identify a given style. The First Number is the nominal diamond dimension Short Way of Design (SWD). The Second Number used in conjunction with the first number MAY specify the gauge of metal, weight per hundred square foot, or may have some other significance. Therefore, the word "GAUGE" SHOULD NEVER BE ADDED TO THE STYLE DESIGNATION. Grating products are designated by weight per square foot of the finished product.

Percent Open Area: The amount of open area to determine the amount of light or air passage.

LWO: Long Way of Opening, the distance measured from the inside of the bond across to the inside of the bond LWD.

Bond: The intersection of two strands and it is always the width of two strands.

Overall Thickness: The actual measurement of the thickness of the mesh measured at the bond.

Standard Expanded Metals: Expanded metal as it comes off the machine. The strands and bonds are set at a uniform angle to the plane of the sheet. This adds strength and rigidity, allows air circulation, distributes the load on the metal to the supporting frames as well as making a skid resistant surface. Standard expanded metal is abbreviated XM.

Flattened Expanded Metal: Manufactured by perforating the standard expanded sheet through a cold roll reducing mill parallel to the LWD. By flattening the sheet, the bonds and strands are turned down to produce a smooth and flat surface, reducing the overall thickness and elongating the diamond pattern (LWD). Cross roll flattening is done by passing the expanded metal sheet through a cold roll reducing mill parallel to the SWD. The result is the same except the diamond pattern SWD is elongated. Flattened expanded metal is abbreviated FXM.

SWD: The distance from a point on a bond to a corresponding point on the following bond measured across the Short Way of Design. This distance is also sometimes referred as "pitch SWD".

LWD: The distance from a point on a bond to a corresponding point on the following bond measured across the Long Way of Design. This distance is also sometimes referred as "pitch LWD".

SWO: Short Way of Opening, the distance measured from the inside of the bond across to the inside of the bond SWD.

Grating: Grating is a standard expanded metal pattern produced from heavier gauge low carbon steel plates. The strands and openings are considerably larger than the other meshes. Ideal for use whenever a strong durable and lightweight surface is required. Although used primarily for pedestrian traffic, grating can accommodate heavier loads when properly supported.

Decorative Patterns: Specially designed expanded metal for use in architectural and decorative applications. These designs can be used to provide privacy and to control light and air while allowing visibility. Sun screens, room dividers, and building facades are only a few of the possible design possibilities. Decorative expanded metal is available in carbon steel, aluminum and other alloys in a wide range of patterns and gauges. Most of these patterns are produced on a special order basis only.

|