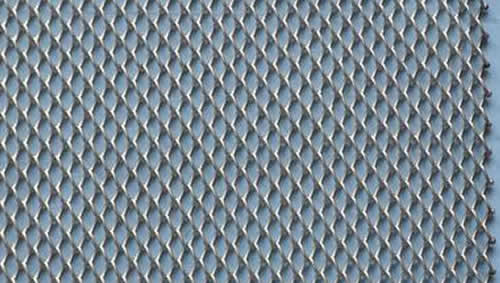

Wall Cladding Panels are mostly framed expanded metal lath cladding panels to internal and external walls made of aluminum material. Details as follow:

a) The wall cladding panels shall comprise expanded aluminium metal lath sheets fixed inside extruded metal framing.

b) Size and configuration of the expanded metal panels shall be as indicated on the Design Drawings. Panels shall be arranged in a staggered pattern.

c) Frames shall be ‘T’ profile, with expanded aluminium metal lath sheets fixed inside so that top edge of frame is exposed. This top edge shall be finished flush with the top of the sheet.

d) Expanded Metal Panels shall be fixed to external walls using a concealed fixing system that facilitates ease of panel removal for cleaning, maintenance and replacement as required.

e) System shall include all secondary steelwork as required.

f) Wall Cladding Panels Fixing system shall allow adequate space for fixing of insulation in areas indicated on the

Design Drawings.

g) Joints: Minimal open joints as indicated on the Design Drawings. Advise the Client’s

Representative if larger joints are required to accommodate thermal expansion.

h) Finish: Natural anodised. The aluminum expanded sheet panels shall be fully fabricated prior to anodising. No cutting or drilling shall be allowed following anodising.

i) Thickness: The Aluminum expanded metal lath panels shall be the following thickness: i) Areas up to 3000mm from finished floor level shall be 5mm thick. ii) Areas above 3000mm from finished floor level shall be 4mm thick.

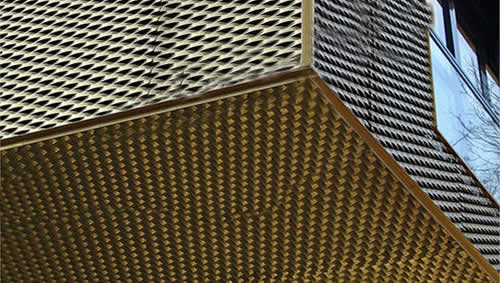

Aluminum Expanded Metal Roof Cladding Panels

Framed expanded metal lath cladding panels to roof areas.

a) Panels shall comprise expanded aluminium metal lath sheets fixed inside extruded metal framing.

b) Size and configuration of panels shall be as indicated on the Design Drawings. Note that various size and shape panels are used for the roof. Panels shall be arranged in a staggered pattern.

c) Where there is not sufficient depth for mesh panels, these shall be substituted for stainless steel blanking panels where indicated on the Design Drawings.

d) Frames shall be ‘T’ profile, with expanded aluminium metal lath sheets fixed inside so that top edge of frame is exposed. This top edge shall be finished flush with the top of the sheet.

e) Panels shall be fixed to secondary steelwork supporting structure using a concealed bracket system as indicated on the Design Drawings. Fixings shall allow panels to be individually removed for cleaning, maintenance and replacement as required.

f) System shall include all secondary steelwork as required.

g) Roof areas shall be designed to accommodate platform and walkway floor loads in accordance with BS 5395.

h) Joints: Minimal open joints as indicated on the Design Drawings. Advise the Client’s

Representative if larger joints are required to accommodate thermal expansion.

i) Finish: Natural anodised. Panels shall be fully fabricated prior to anodising. No cutting or drilling shall be allowed following anodising. Refer to Section Z33.

j) Thickness: Expanded metal lath panels shall be 5mm thick. Contractor shall confirm

Expanded Metal Cladding Support System

Provide a structural steel cladding support system, as necessary, having due regard for any requirements in excess of primary structure indicated on the Structural Engineer's Drawings and also any requirements indicated on the Design Drawings. The support system shall comply with the Structural Engineer's Steelwork Specification, including protective coatings.

Fixings

a) Primary external fastenings: Stainless steel fasteners to BS 5427, grade 1.4401 (equal to

BS EN ISO 3506: Parts 1 and 2 grade A4 or acceptable equivalent) to BS EN 10088, or

b) Mild steel to BS 4190 and suitable for galvanising or other protective coating, or

c) Aluminium complying with BS EN 755: Parts 1-9, BS EN 573: Part 3, BS EN 515 and BS EN 12020: Parts 1 and 2 for brackets, rivets and shear pins.

Fixing Anchors

a) Refer to Section Z20 for fixings generally.

b) Shall be of dimensions not less than those recommended by their manufacturers.

c) Shall be capable of adequate three-dimensional adjustment to accommodate building structure and cladding fabrication/installation tolerances.

d) All fixing anchors shall be stainless steel grade 1.4401 and shall be to the requirements of the Building Control Officer.

|